How Do Air-Blown Micro Cables Maintain Flexibility While Being Robust?

In the ever-evolving landscape of fiber optic technology, air blown micro cables have emerged as a game-changing solution for high-density network deployments. These cables must strike a delicate balance—offering exceptional flexibility for easy installation while maintaining the robustness required for long-term durability. Achieving this duality demands advanced engineering, innovative materials, and precision manufacturing techniques.

Material Science: The Backbone of Flexibility and Strength

The foundation of air blown micro cables lies in their specialized construction. Unlike traditional fiber optic cables, which rely on rigid outer sheaths, these micro cables incorporate high-performance polymers with tailored mechanical properties. Thermoplastic elastomers (TPE) and polyethylene (PE) are commonly used due to their ability to withstand mechanical stress while preserving flexibility.

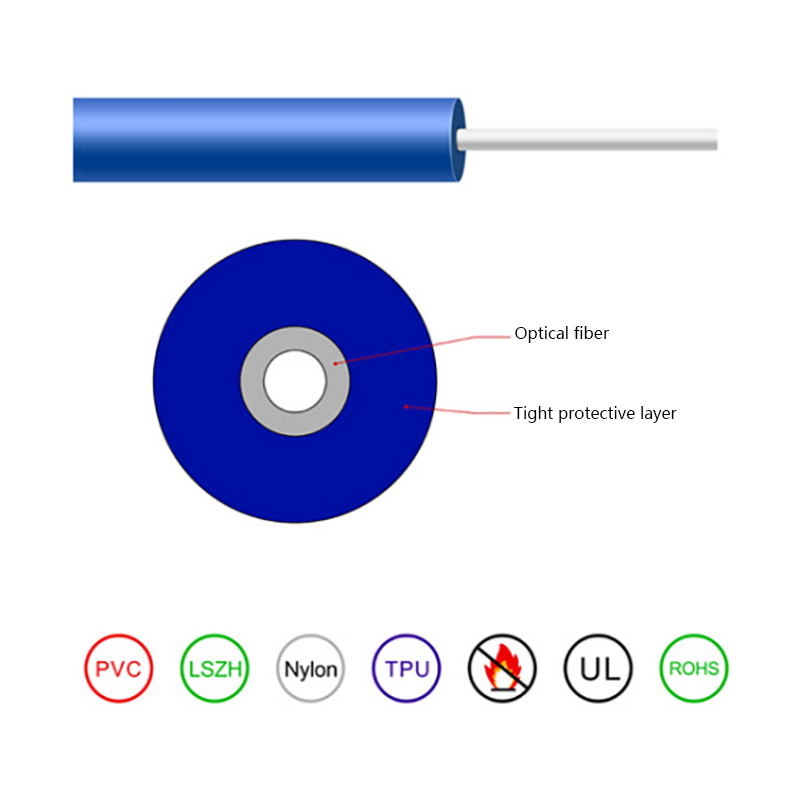

Additionally, advanced buffer coatings protect the delicate optical fibers from microbending and environmental stressors. These coatings, typically made from acrylate-based compounds, provide an optimal blend of elasticity and resilience. The result is a cable that remains pliable even when subjected to repeated bending, pulling, or compression.

Optimized Cable Architecture for Superior Performance

Beyond material selection, the internal design of air blown micro cables plays a pivotal role in their durability. Engineers employ several key strategies to ensure both flexibility and robustness:

1. Central Strength Members

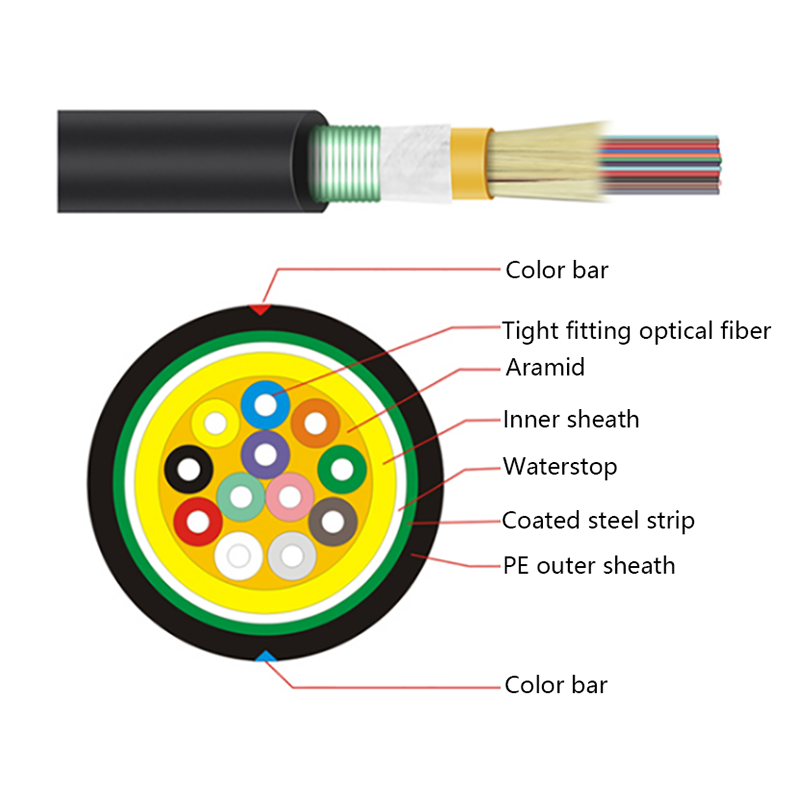

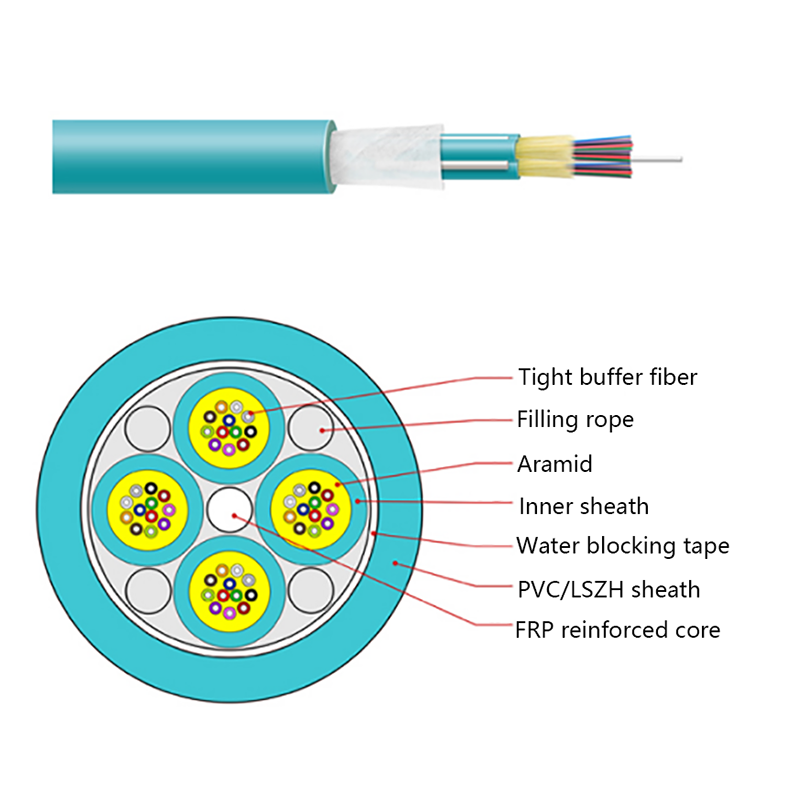

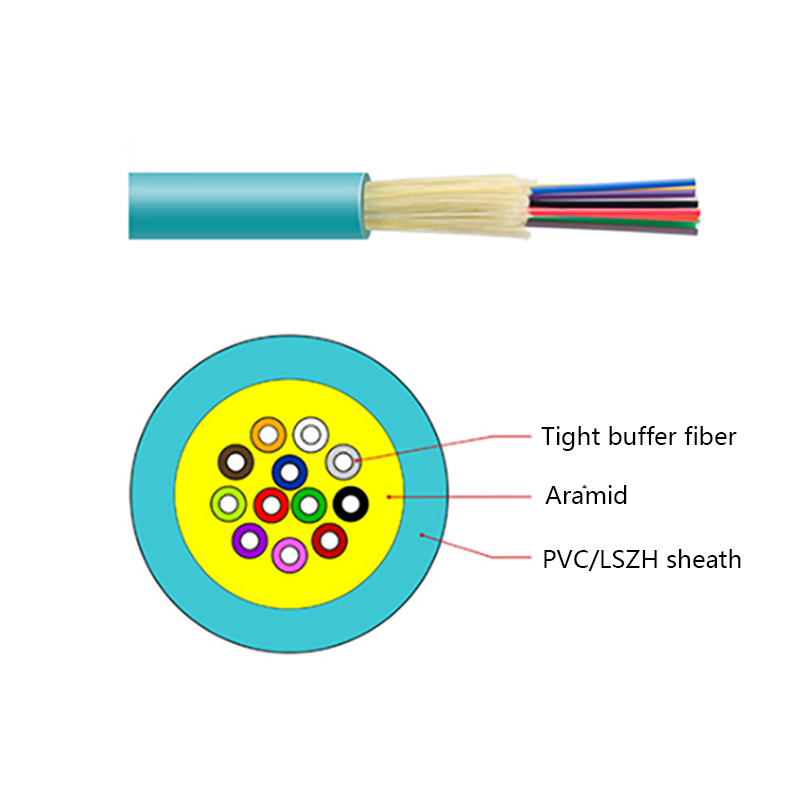

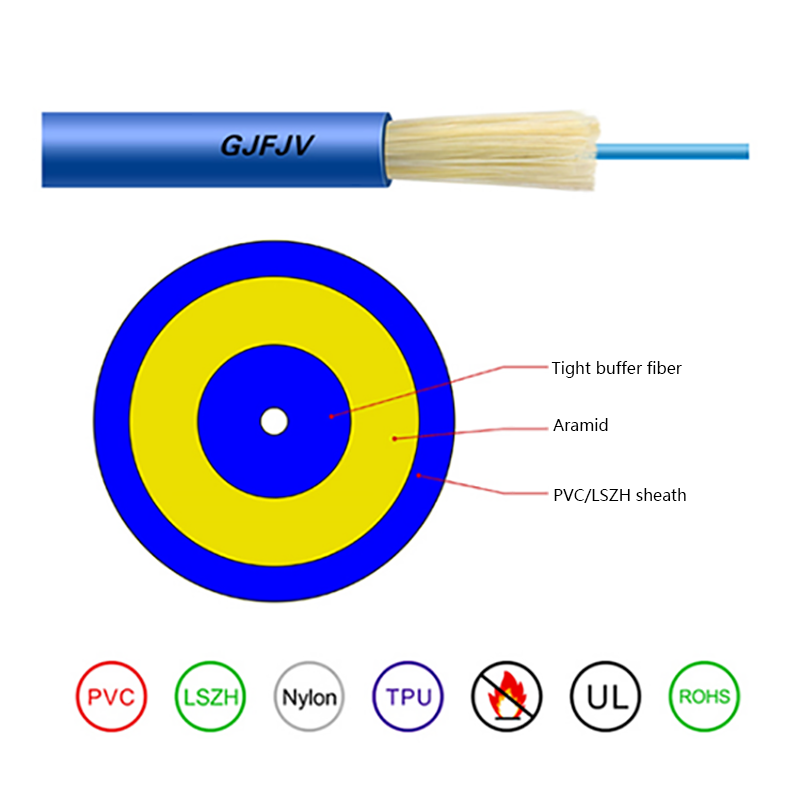

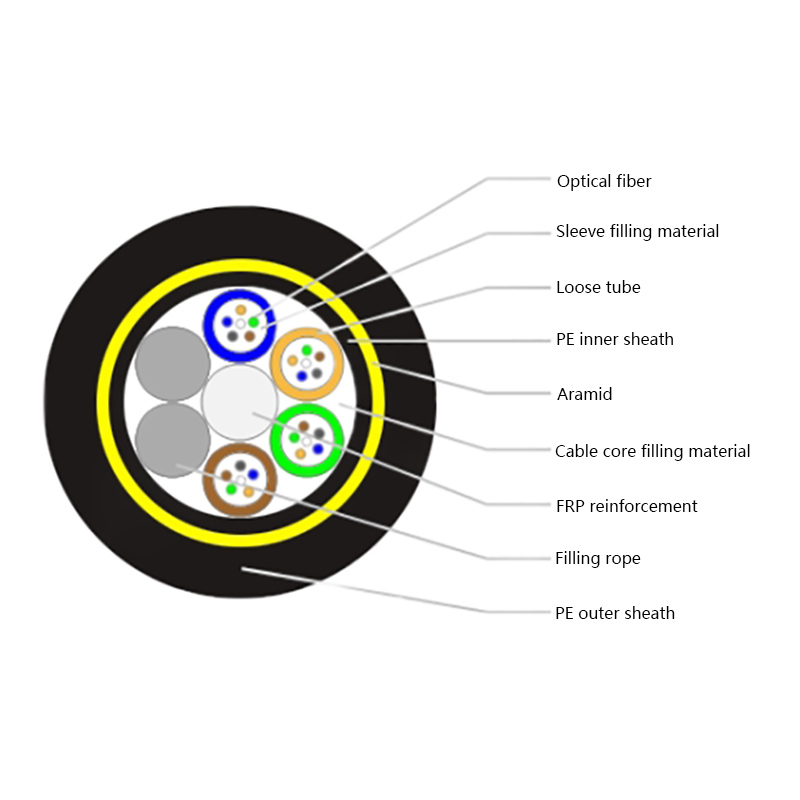

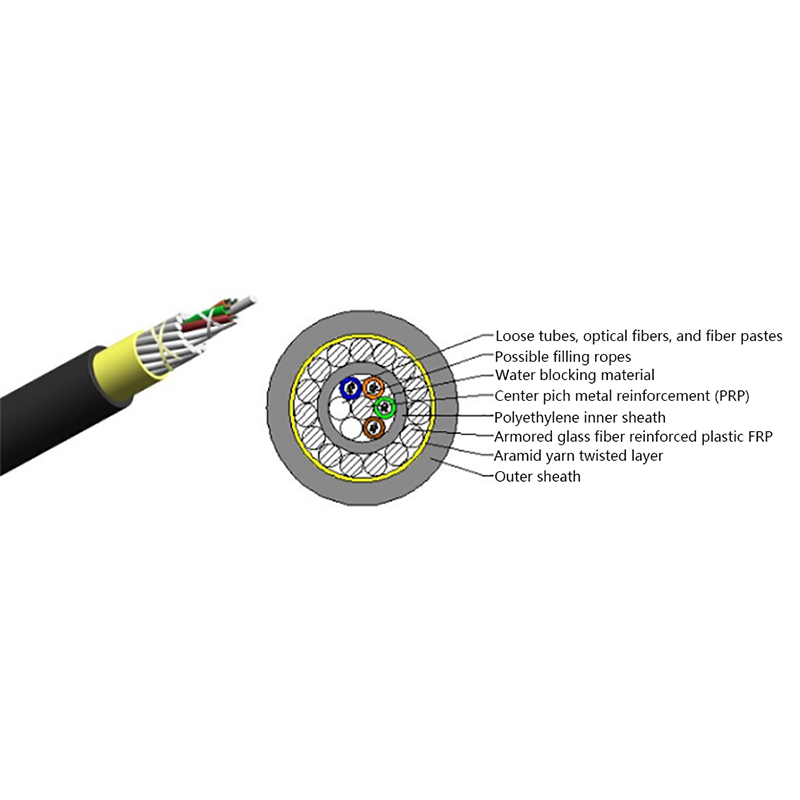

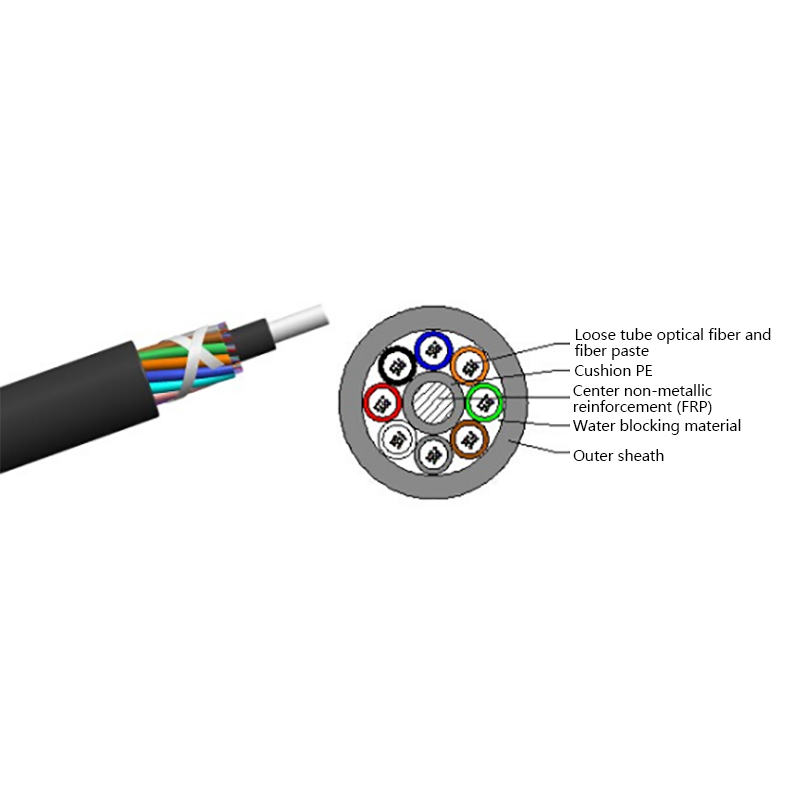

To prevent excessive strain on optical fibers, air blown micro cables often feature a central strength member. This component, typically constructed from aramid yarns or fiberglass-reinforced plastic (FRP), acts as a structural backbone, absorbing tensile forces while allowing the cable to bend without damage.

2. Loose-Tube Construction

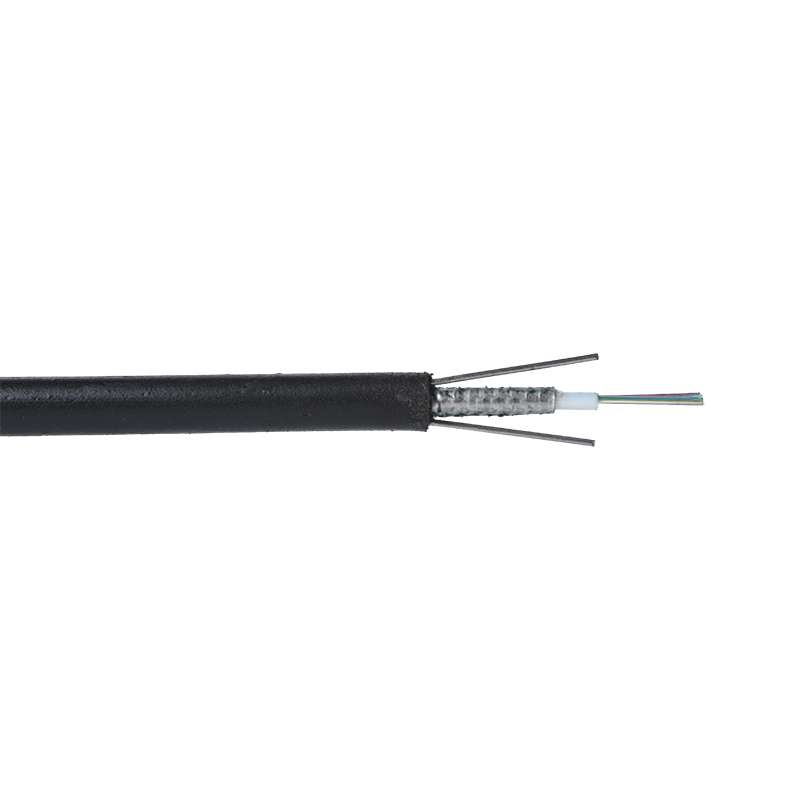

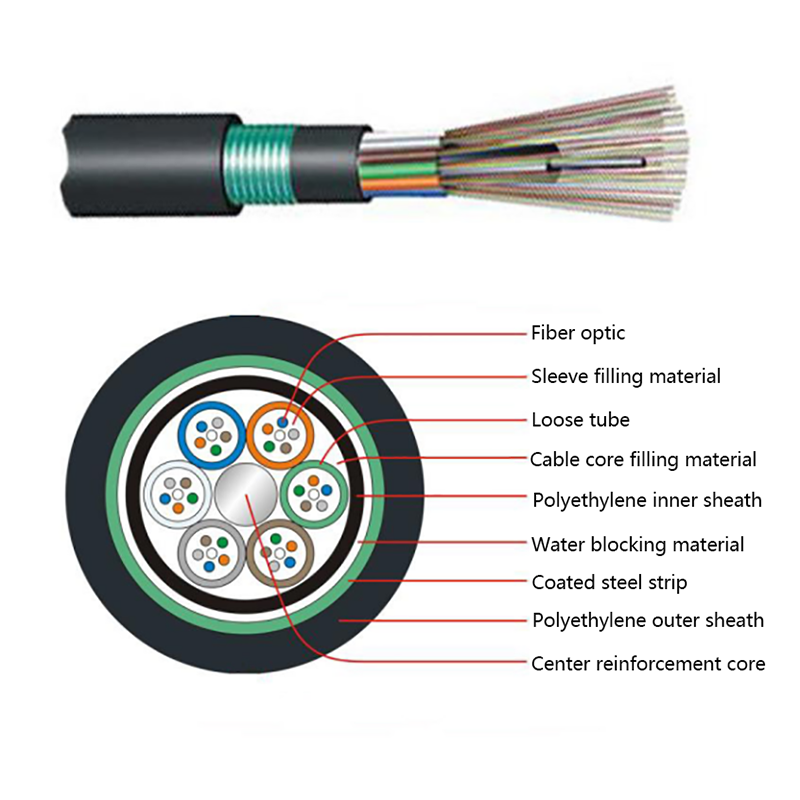

Many air blown micro cables utilize a loose-tube design, where optical fibers are housed within gel-filled or dry buffer tubes. This configuration provides an additional layer of protection, shielding the fibers from external pressures while allowing them to move freely within the tube. Such an approach minimizes signal loss due to stress-induced attenuation.

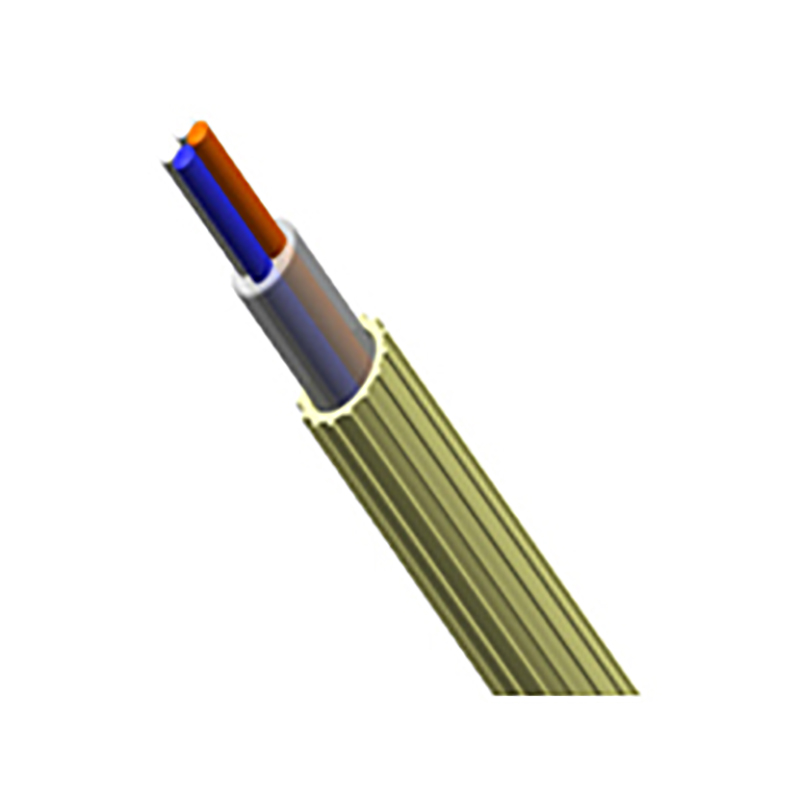

3. Micro-Sized Outer Sheaths

Unlike conventional fiber optic cables, air blown micro cables feature ultra-thin yet resilient outer sheaths. These sheaths reduce overall weight and diameter, facilitating easier deployment in microducts. At the same time, they provide essential protection against moisture, abrasion, and temperature fluctuations.

Air blown Installation: Enhancing Longevity Through Reduced Mechanical Stress

One of the primary advantages of air blown micro cables is their installation method. Rather than being pulled through ducts—an approach that subjects cables to high tensile forces—these cables are propelled using compressed air. This frictionless deployment significantly reduces mechanical stress, preserving the cable’s structural integrity over time.

Additionally, air blown installation allows for modular network expansion. Instead of overbuilding fiber capacity upfront, operators can incrementally add cables as demand grows. This future-proof approach not only optimizes costs but also minimizes wear and tear on existing infrastructure.

Resilience Against Environmental Challenges

For air blown micro cables to maintain long-term performance, they must endure a variety of environmental stressors. These include extreme temperatures, humidity fluctuations, UV exposure, and mechanical shocks. To address these challenges, manufacturers incorporate several protective enhancements:

UV-resistant coatings prevent degradation in outdoor deployments.

Water blocking compounds protect against moisture ingress, ensuring long-term optical performance.

Impact-resistant designs allow cables to withstand accidental crushing or bending during handling.

Air blown micro cables exemplify the perfect synergy between flexibility and resilience. Through cutting-edge materials, innovative design principles, and air-assisted installation methods, these cables achieve unparalleled performance in modern fiber optic networks. As demand for scalable, high-bandwidth connectivity continues to rise, air blown micro cables stand as a testament to the power of precision engineering in telecommunications infrastructure.

English

English русский

русский Español

Español عربى

عربى 中文简体

中文简体