How are all dielectric self supporting cables protected from high electrical field stress in power line applications?

In the ever-evolving world of electrical engineering, the demand for reliable and efficient power transmission continues to rise. One of the innovations making waves in this realm is theall dielectric self supporting cables. With its ability to operate in high-voltage environments without the need for metallic components, ADSS cables are becoming the go-to choice for many utility companies. However, with great power comes great responsibility, especially when it comes to protecting these cables from high electrical field stress.

Understanding High Electrical Field Stress

High electrical field stress can be a major concern for power line applications, particularly in environments with extreme weather conditions or high voltage. When electrical stress exceeds a certain threshold, it can lead to dielectric breakdown, resulting in insulation failure and potential outages. For ADSS cables, which are primarily made of non-metallic materials, understanding the implications of high electrical fields is crucial. The insulation properties of these cables must withstand high voltage surges while maintaining their structural integrity.

Design Innovations for Enhanced Protection

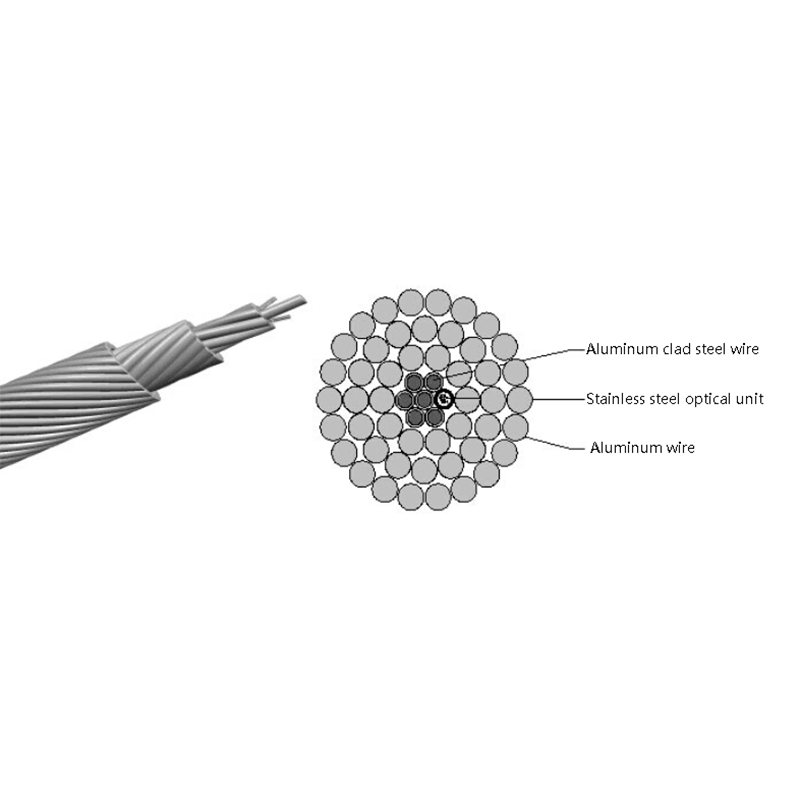

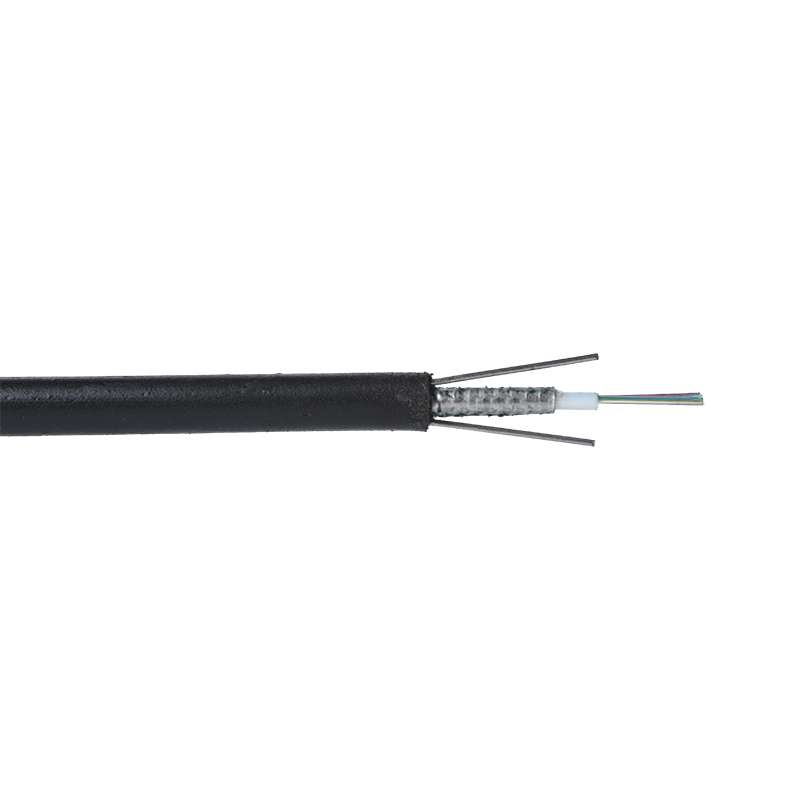

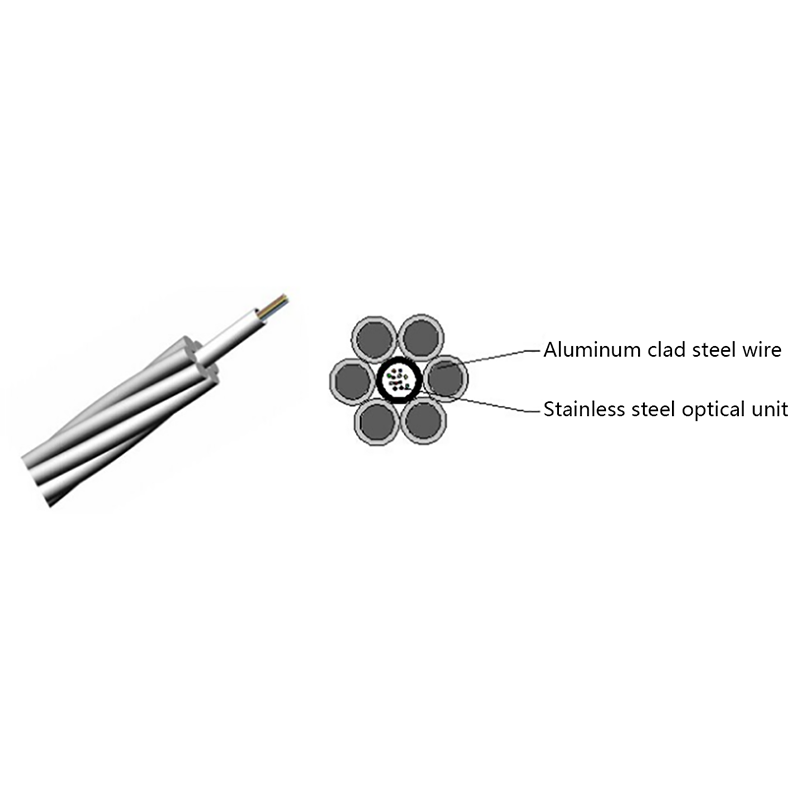

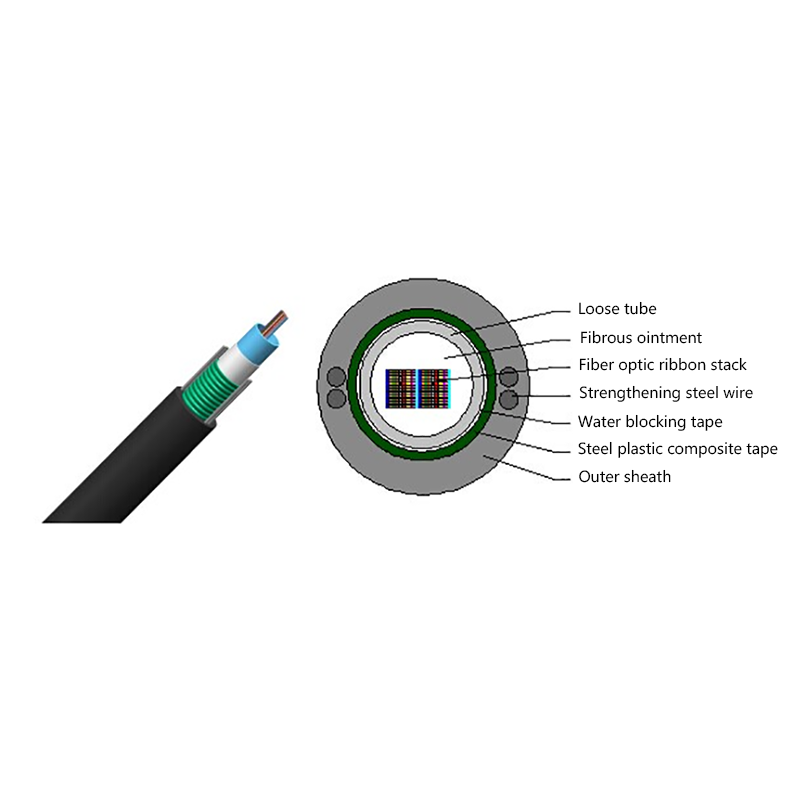

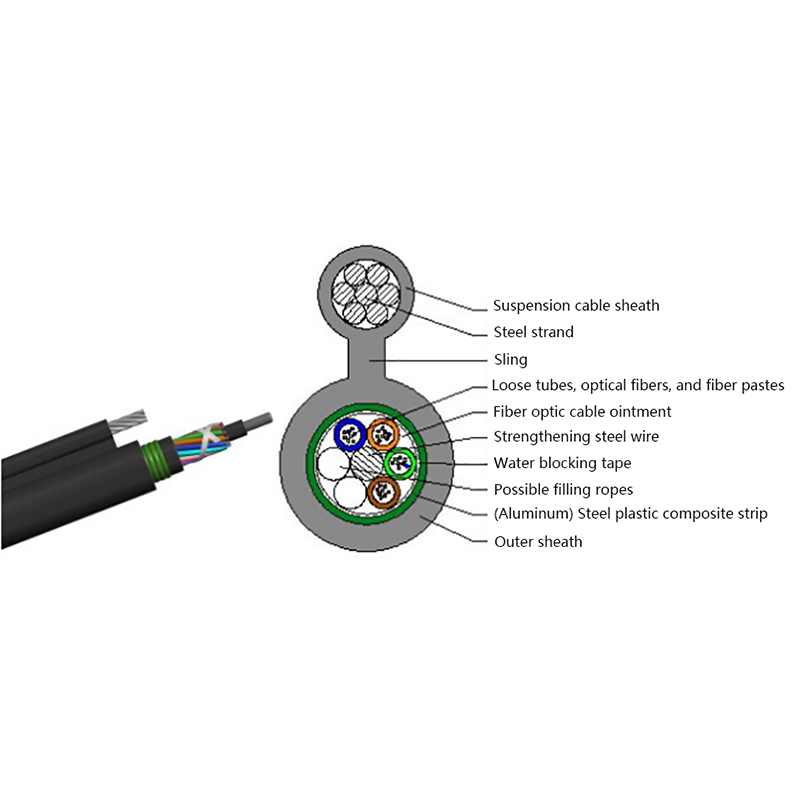

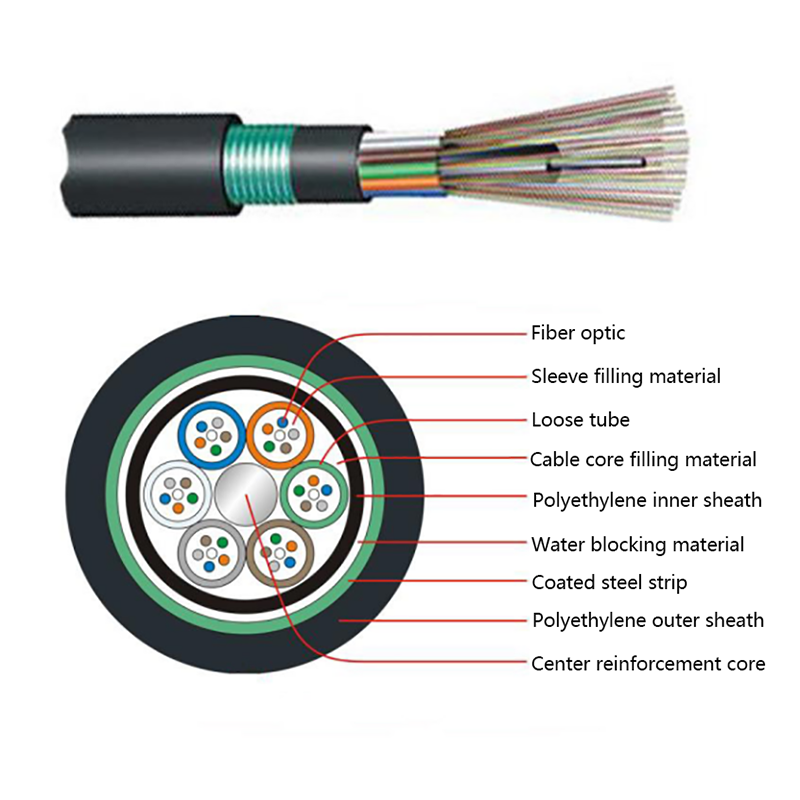

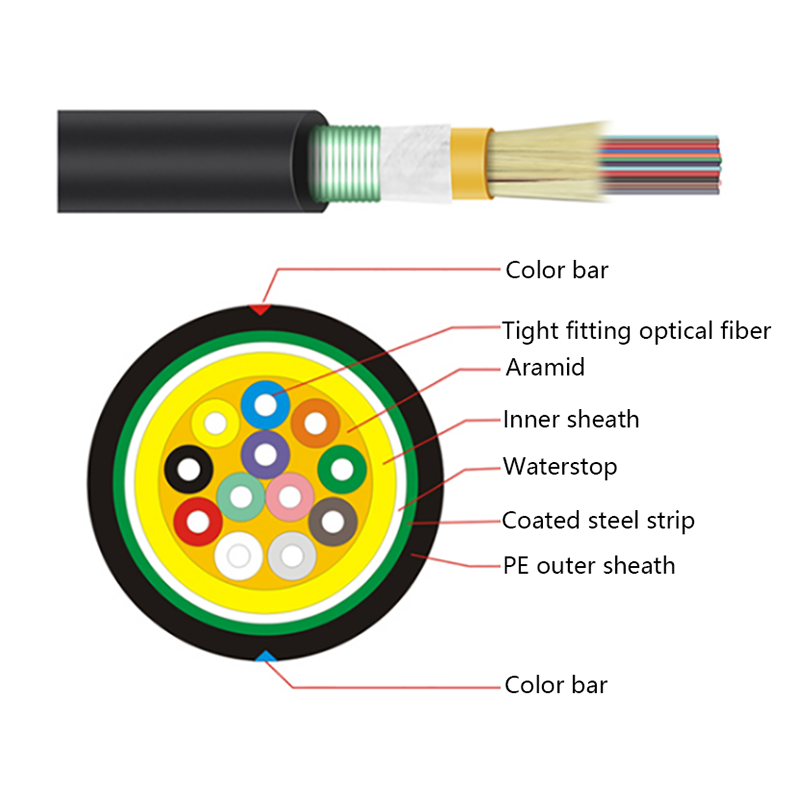

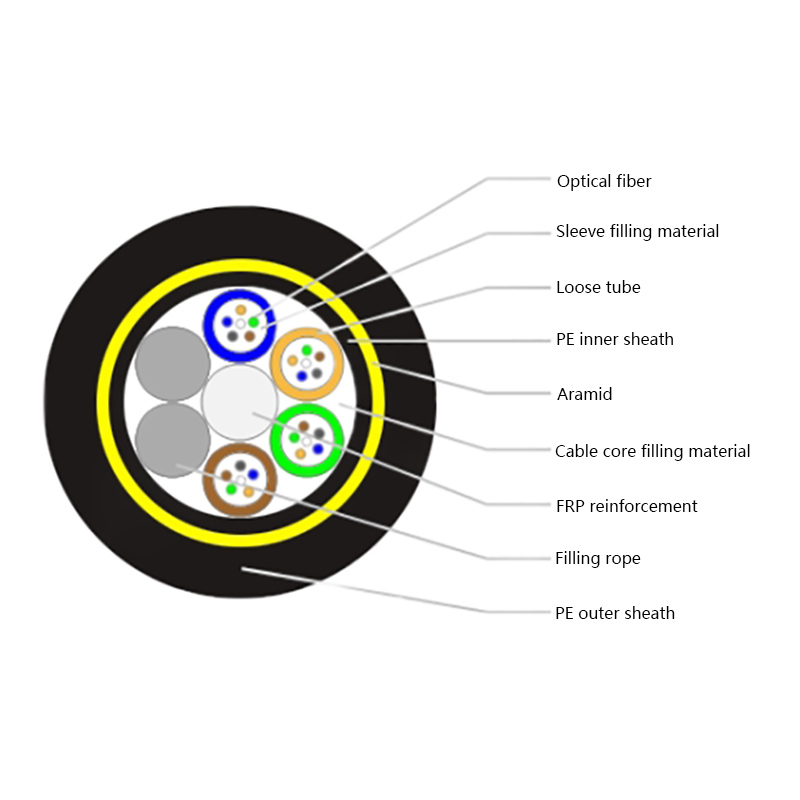

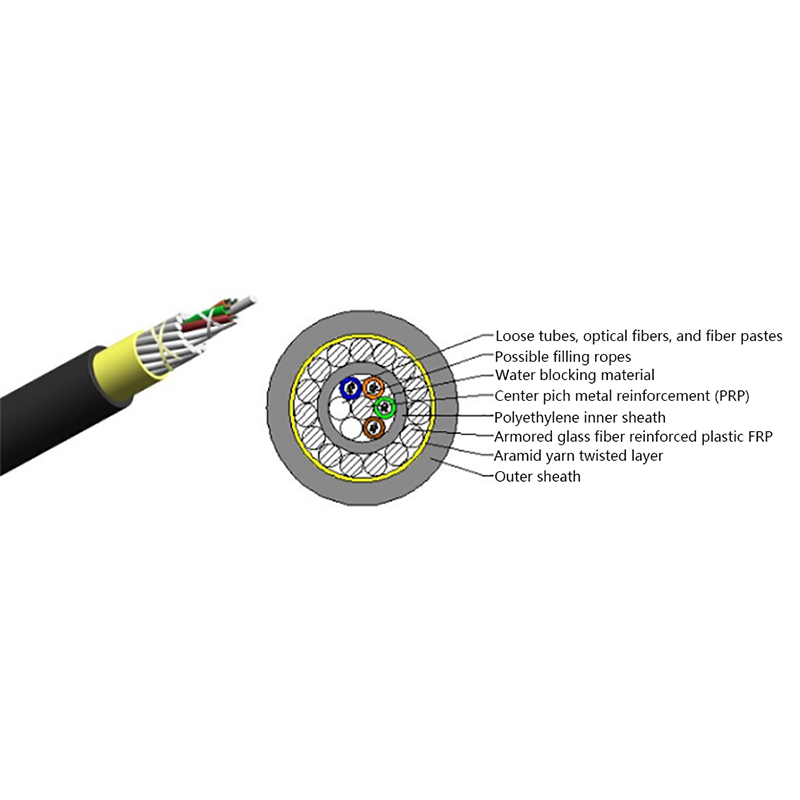

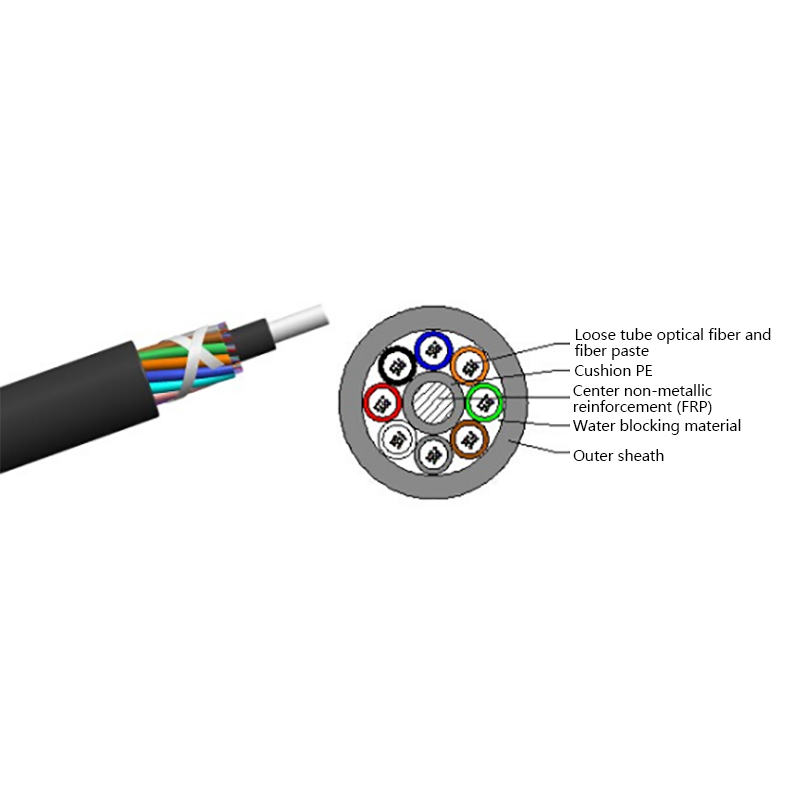

To combat high electrical field stress, engineers have employed innovative design strategies for ADSS cables. One such method is the use of advanced polymer materials that offer superior dielectric properties. These materials not only improve the insulation but also provide better resistance to environmental factors such as UV radiation and moisture. Additionally, the cables are designed with a specific geometry that helps distribute electrical stress more evenly along the length of the cable, minimizing localized stress points that could lead to failure.

Installation Techniques That Mitigate Risks

Proper installation techniques are equally important in protecting ADSS cables from high electrical field stress. Utility companies often employ specialized installation methods that ensure the cables are tensioned correctly, reducing stress on the materials. Furthermore, the use of protective hardware, such as tension clamps and strain relief devices, plays a vital role in maintaining the integrity of the cable during installation and throughout its operational life. These techniques are essential in ensuring that the cables can withstand the rigors of their environment while continuing to function efficiently.

Monitoring and Maintenance for Long-Term Reliability

Even with robust design and installation methods, ongoing monitoring and maintenance are crucial for ensuring the longevity of ADSS cables. Many utility companies have begun incorporating smart technology, such as sensors and monitoring systems, that can detect changes in electrical field stress in real time. This proactive approach allows for timely interventions, preventing potential failures and costly outages. Regular inspections and maintenance schedules further enhance the reliability of these cables, ensuring they continue to perform at optimal levels.

As the world moves towards more sustainable and efficient power transmission solutions, All Dielectric Self-Supporting cables stand out as a remarkable innovation. The protection against high electrical field stress is a multifaceted approach that combines advanced materials, innovative design, meticulous installation, and proactive monitoring. By implementing these strategies, utility companies can ensure the reliability and longevity of ADSS cables, ultimately contributing to a more resilient power grid. As we continue to embrace these technologies, the future of power transmission looks brighter than ever.

English

English русский

русский Español

Español عربى

عربى 中文简体

中文简体