Features:

1. Good flexibility 2. Good stability 3. Good reliability 4. High strength

Classification

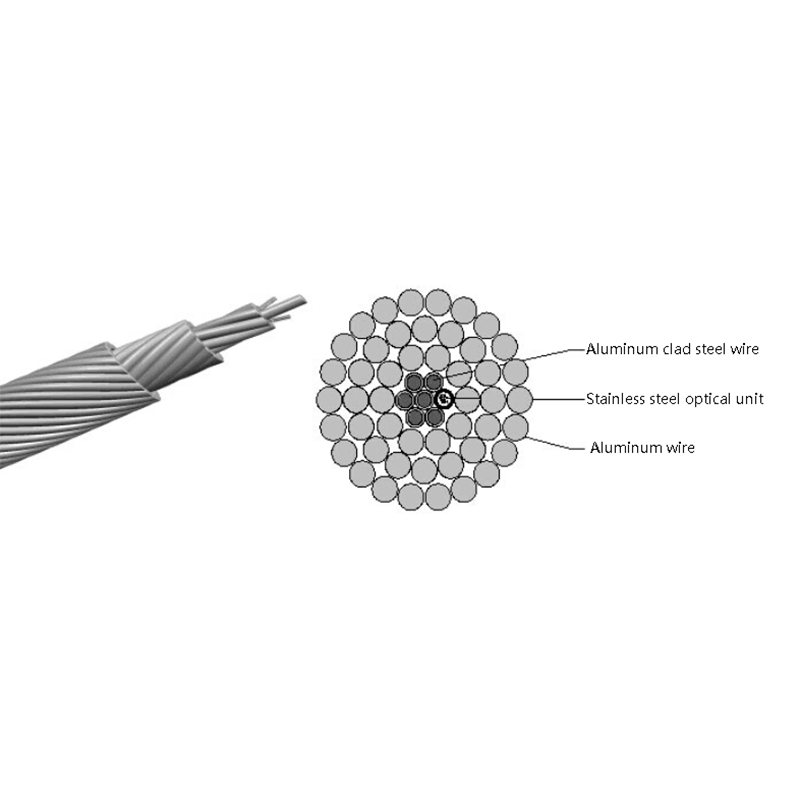

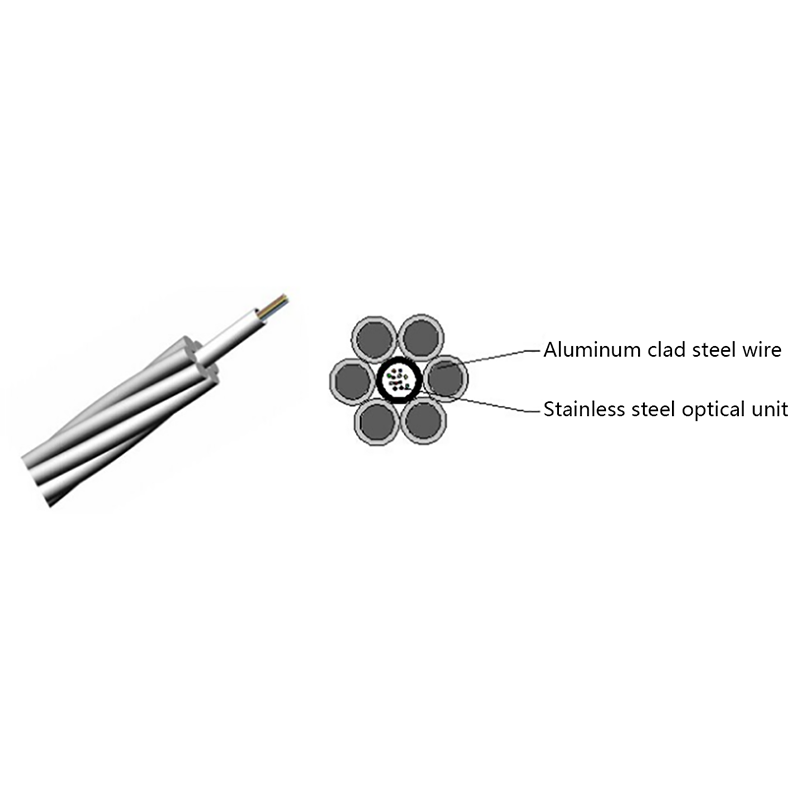

a. Steel strands are divided into four types according to their cross-sectional structures.

1×3 1×7 1×19 1×37

b. The national standard steel strand is divided into five levels according to the nominal tensile strength: 1270MPa, 1370MPa, 1470MPa, 1570MPa, and 1670MPa.

c. According to the different thickness of the zinc layer of the steel wire in the galvanized steel strand, the level of the zinc layer of the steel wire in the national standard steel strand is divided into three levels: A, B, and C.

3 technical requirements

Dimensions and accuracy

1. The diameter of the steel wire in the steel strand and its allowable deviation.

2. The twist length of the steel strand should not be greater than 14 times its diameter. Other multiples of lay length should be specified in the contract

3. The outermost layer of the steel strand is twisted to the right. The twist direction of the outermost steel wire should be opposite to that of the adjacent inner wire, as shown in the figure below. If the twist direction needs to be changed, it should be noted in the contract. Strand twist direction The twist direction of the steel strand should be left-hand (S).

4. When there are no special requirements, the length of the steel strand shall not be less than 200m, and the length deviation is:

Nominal length tolerance

<1000m +3%

≥1000m +1.5%

raw material

Steel wires for steel strands should be manufactured according to YB/T 170.2 and wire rods specified in GB/T 4354. The grade is chosen by the supplier.

Zinc ingots used for galvanizing steel wires should use Zn99.995 zinc ingots in GB/T 470.

Stranding process requirements

1. The galvanized steel wires (including the center wire) in the steel strand should be of the same diameter, the same strength, and the same zinc layer level.

2. The diameter and lay length of the steel strand should be uniform and not loose after cutting.

3. The steel wires in the steel strand should be tightly twisted and should not be staggered, broken or bent.

4. The steel strand should be straight, soft, and have small residual stress. It should not have a ∽ shape after unfolding.

5. No joints are allowed in 1x3 structural steel strands and overhead ground wires. The steel wire joints in other types of steel strands should be welded butt joints. The distance between any two joints should not be less than 50m and the joints should be treated with anti-corrosion treatment.

English

English русский

русский Español

Español عربى

عربى 中文简体

中文简体