Hawell R & D manufacturing center

Continuous innovation to bring you the global advanced solutions for your network.

We continue to introduce advanced technology and strengthen quality. Actively layout 5G. Seize the commanding heights of the industry, and enjoy a high reputation in domestic and foreign markets. Hawell Optoelectronics continues to focus on the research and development and production of optical cables, and promotes the universal use of optical cables in China and the world. So that everyone in the world can enjoy the happiness of optical cable communication.

Professional fiber optic

Cable technicians

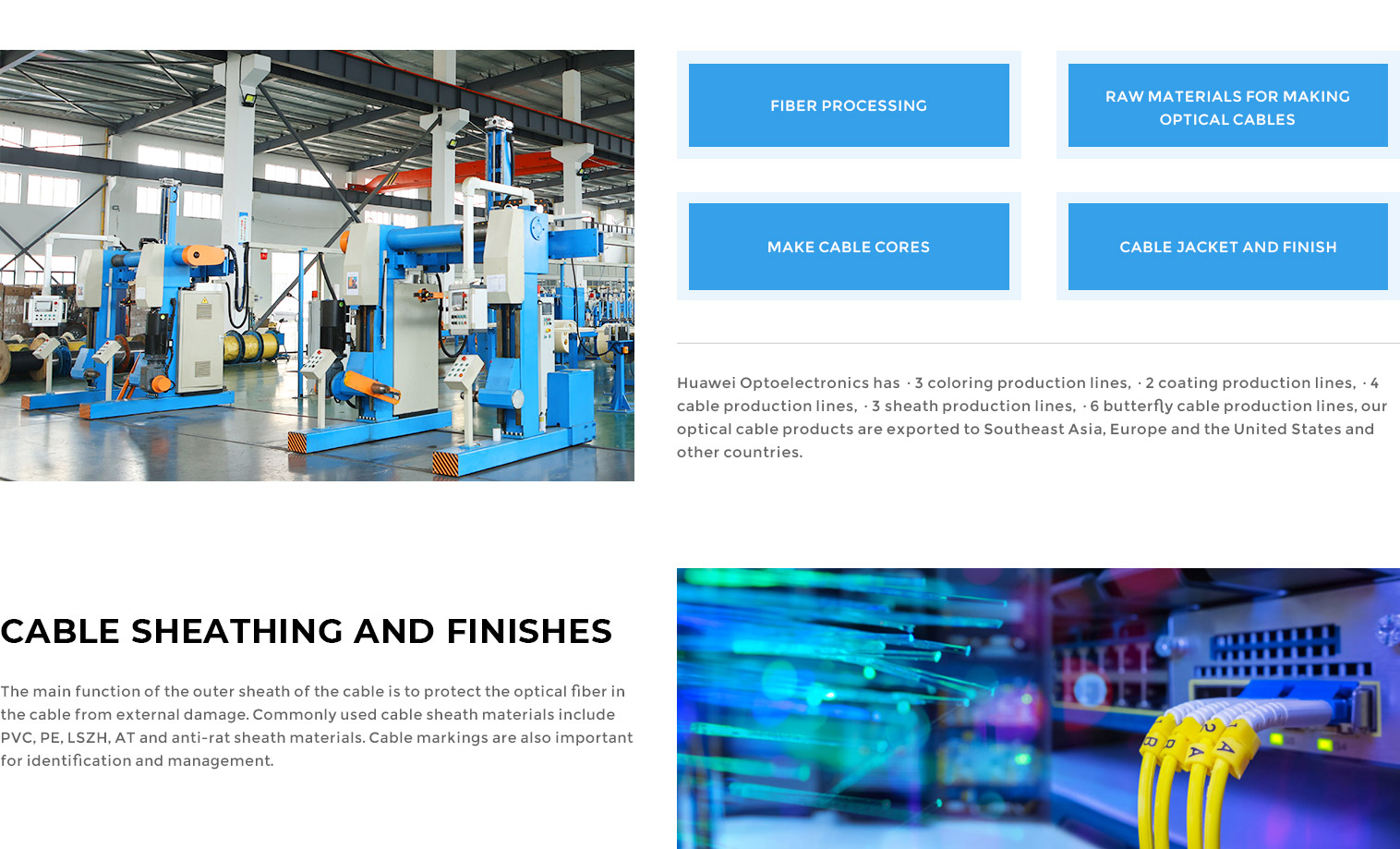

Hawell Optical Cable Manufacturing Plant is equipped with advanced machinery managed by highly skilled technicians, which allows us to produce high quality optical fiber cables with high efficiency and low cost.

Fiber optic cable manufacturing link

The manufacture of optical cables involves several stages. They include coloring and other material layers, armor, sheathing processes, and packaging. The manner in which these steps are performed can be adjusted depending on the fiber optic cable product.

Our testing center

Every delivery is subject to rigorous quality testing.

Professional equipment display

Spectrum analyzer, metallographic microscope, universal tensile testing machine, impact testing machine, torsion testing machine, flattening testing machine, image measurement.

English

English русский

русский Español

Español عربى

عربى 中文简体

中文简体